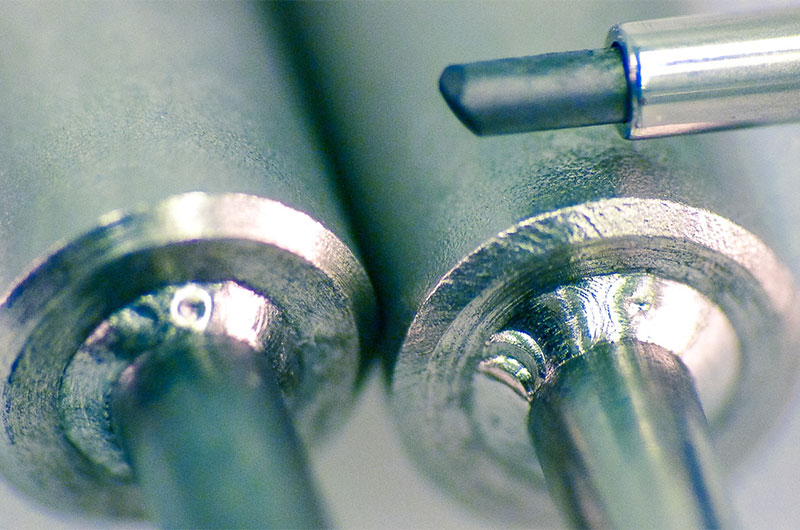

Laser microwelding

MICROWELDING

Laser microwelding explained in a few words:

Laser microwelding is a fusion welding process performed with or without the addition of filler metal. The light energy is concentrated on a small area (a diameter of 0.02mm to 2mm) during a short period of time (approximately 2 to 50 ms). This reduces the heat affected zone (HAZ) , which minimizes distortion while allowing to weld in close proximity to sensitive materials such as polymers or composites. Our control of the welding parameters (i.e. pulse duration, , frequency and intensity) allows us to optimize the welding parameters for specific alloys.

Alloys frequently welded by this process are:

- Stainless Steels

- Nickel Alloys

- Titanium

- Platinum Alloys

- Gold

We keep an inventory of filler metals from different alloys with diameters ranging from 0.003” to 0.020”. The use of a microscope and digital controls ensure an excellent repeatability of results as well as an exceptional welding quality.

Would you like more information on our laser microwelding services? Contact us!

Contact our experts and let us take care of all the products and services required for your control and instrumentation needs!