Sensors for generators and large motors

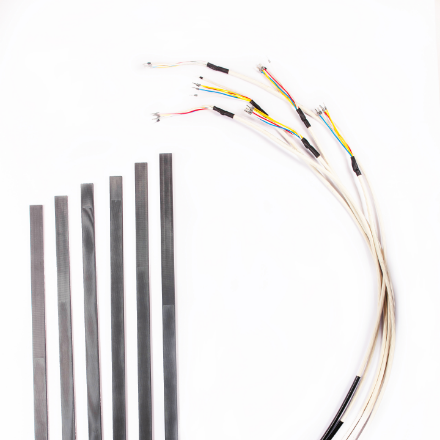

Stator Winding RTD

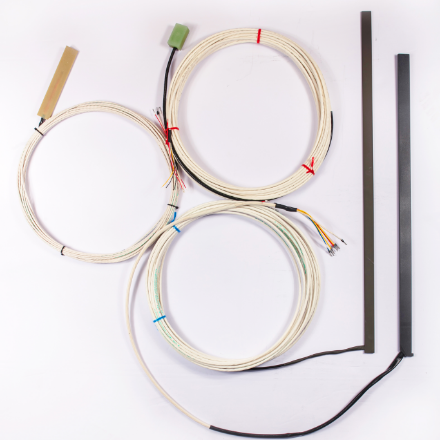

Our DynaWind Sentinel RTDs, developed in collaboration with the C2Mi and the CRIQ, are the epitome of high reliability in temperature monitoring for large motors and generator windings with advanced features to detect hotspots and ensure the safe operation of critical equipment. The collaboration between our organizations guarantees innovation and an ongoing commitment to reliability.

Recognized by the National Electrical Manufacturers Association (NEMA), these flat, laminated “stick” RTDs provide continuous temperature sensing for early warnings when needed. When reliability is paramount, our DynaWind Sentinel RTDs stand out as the only solid choice. We know that dependable sensors are a non-negotiable asset, particularly in critical applications. When the stakes are high, you can rely on our product to ensure the longevity and safety of your motors and generators. DynaWind Sentinel RTDs, when reliability matters!

Design

-

True bifilar, non inductive, wire-wound single or dual elements

-

Heavy gauge platinum for extreme stress resistance

-

Custom CNC machined to tight tolerances

-

Unique monolithic design with unparalleled compressive strength

-

Insulating or semi-conductive laminates

-

Semi-conductive coatings with controlled surface resistance

-

Custom designs tailoured to your specific requirements

-

Highly flexible manufacturing capabilities

-

Engineering support with detailed drawings and documentation

-

Integral wire strain design

Work with Dynatherm to fulfill all your sensor and accessory needs today!

Specifications

-

Thickness options: Min. 0.1” to 0.375”

-

Width options: Min. 0.375”

-

Temperature limit: 180°C (356°F), Class H

-

Body material: High-temperature epoxy glass (G11 Class H) or semi-conductive glass (Class H)

-

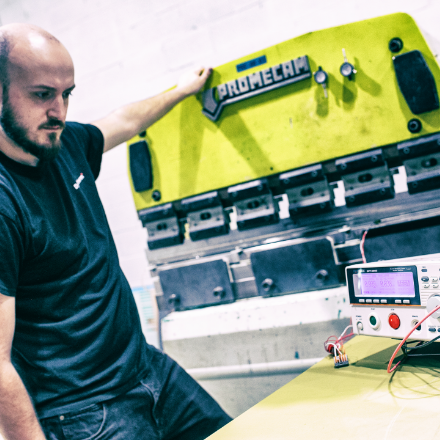

High-voltage testing up to 5 kVAC under static load (typical 120 PSI loading during testing)

Benefits

-

High reliability for critical applications

-

Successfully tested up to 8,000 hours at 160°C and 4,000 cycles from -25°C to 160°C to simulate 25 years of operation in large generator winding

-

100% high-voltage load tested to 120 PSI up to 5 kVAC

-

HVLP semi-conductive coating application guarantees uniform coating and probe thickness

-

Monolithic, CNC-machined components with stress bypass channels to ensure unparalleled compressive strength

-

Extreme G-shock resistance

-

Each probe is tested in a climate chamber with calibration results

-

Unique test report with results of dimensional, electrical and temperature testing

-

Corona-resistant designs

-

Vacuum filling ensuring void-free construction

-

Complete portfolio of custom probes (Stator core, stator duct, SAC, bearing, turbine temperature sensors, etc.)

Contact our experts and let us take care of all the products and services required for your control and instrumentation needs!